Cooking Agave

The cooking stage is essential in mezcal production, transforming the raw agave into a flavorful and fermentable base. This process adjusts the acidity levels (pH) and converts inedible fructans into fermentable sugars like fructose, glucose, and sucrose. Cooking agave plays a pivotal role in shaping mezcal’s unique flavors and aromas.

Each type of mezcal—mezcal, artisanal mezcal, and ancestral mezcal—relies on specific cooking methods that influence its style, quality, and production scale. Let’s explore the fascinating process of cooking agave and how different techniques contribute to the final product.

Why Cooking Agave Matters

Cooking agave is more than just a preparatory step; it is where raw materials are transformed into fermentable sugars. The heat breaks down the agave’s fructans (complex carbohydrates), creating sugars that can be fermented. Agave cooking also helps release various compounds contributing to mezcal’s distinctive taste profile. Depending on the chosen cooking method, these flavors can range from smoky and earthy to clean and subtle.

The method of cooking also determines the efficiency and scale of production. For example, small-scale producers often use traditional techniques that emphasize quality and flavor complexity, while large-scale operations may opt for faster methods to maximize output.

Cooking agave is more than just a preparatory step; it is where raw materials are transformed into fermentable sugars.

The Impact of Cooking on Flavor

Cooking agave is not just a technical step; it’s a creative process that directly influences the mezcal’s final character.

Each cooking method produces distinct compounds that contribute to the following:

- Aroma: Subterranean ovens yield smoky and earthy notes, while autoclaves produce cleaner, subtler aromas.

- Taste: Traditional methods emphasize depth and complexity, whereas industrial methods focus on efficiency and consistency.

- Color: Depending on the technique, the cooked agave’s caramelization can slightly influence the color of the mezcal.

Methods of Cooking Agave

Four primary methods are used to cook or roast agave in mezcal production. Each method impacts the mezcal’s flavor profile, production efficiency, and style.

Traditional Methods

Traditional cooking methods, such as subterranean ovens, play a crucial role in preserving mezcal’s cultural and artisanal heritage. These techniques prioritize quality by enhancing flavor complexity and authenticity. They also emphasize sustainability, often utilizing renewable resources like local wood for roasting. These methods are significant for their cultural connections, linking mezcal to its historical roots and enriching its overall identity.

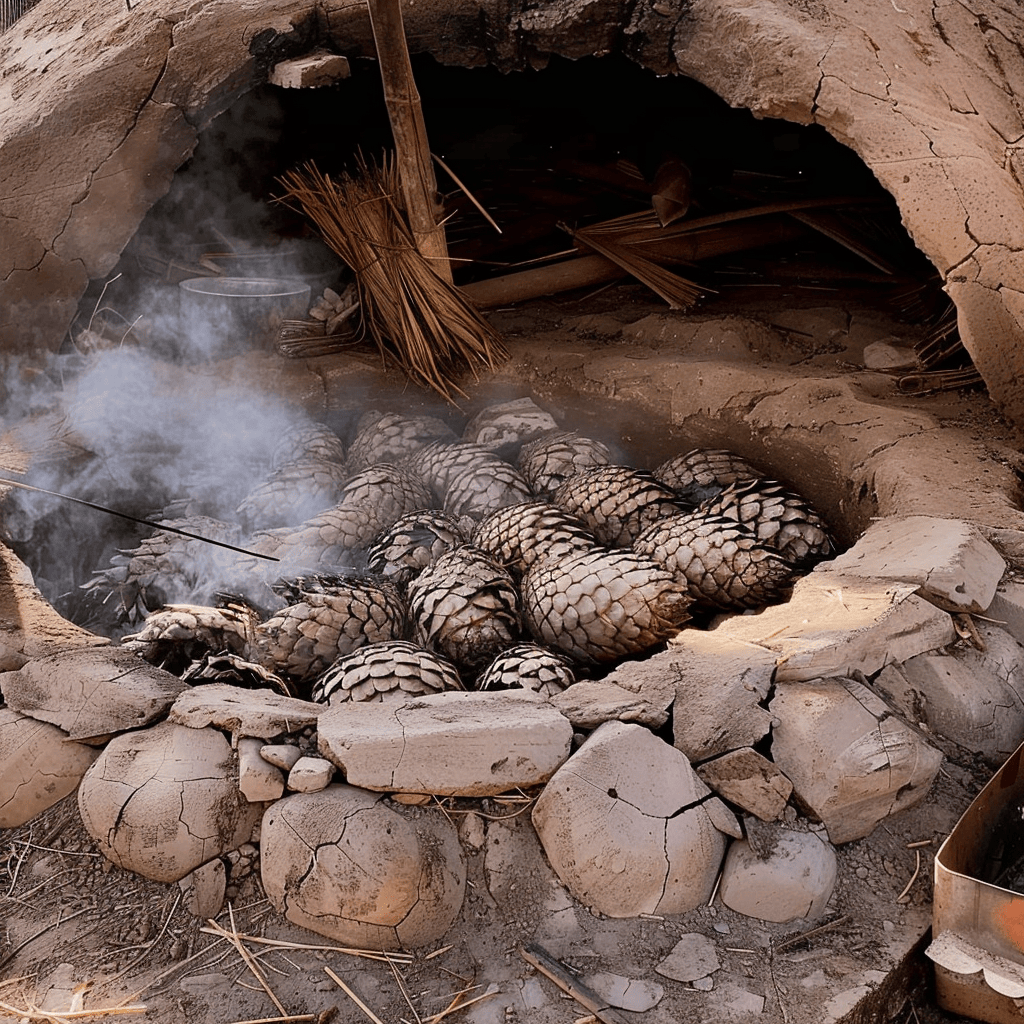

Subterranean Oven Method

The subterranean oven method is the most traditional and artisanal approach, dating back thousands of years.

- Process: Agave hearts (piñas) are buried in an earthen pit lined with heated volcanic stones and covered with layers of agave fiber, soil, and leaves. The agave is roasted for 5 to 30 days, depending on factors like the size of the piñas, weather conditions, and wood type used.

- Flavor Impact: This method imparts mezcal’s signature smoky flavor and a rich, complex aroma that aficionados prize.

- Challenges: Maintaining consistent temperatures can be brutal, and the process is labor-intensive.

Masonry Oven Method

The masonry oven method bridges the gap between traditional and industrial techniques.

- Process: Agave is roasted in brick or stone ovens for 48 to 72 hours, allowing for a more gradual breakdown of sugars.

- Usage: Popular in regions like Jalisco, Zacatecas, and San Luis Potosí.

- Flavor Impact: Produces flavors similar to autoclave-cooked agave but slightly more complex due to the slower process.

Modern Methods

Modern techniques like the diffuser and autoclave are designed to enhance mezcal production in several key ways. They aim to increase efficiency by reducing cooking times and boosting yields while standardizing production to ensure consistency across large batches. These innovations are essential for meeting the rising global demand for mezcal, allowing producers to cater to the expanding market with high-quality products.

Diffuser Method

The diffuser method, also known as the “green method,” is one of the most efficient techniques for extracting sugars. Here’s how it works:

- Process: The agave is shredded, and the juices are extracted using chemicals like sulfuric acid and ammonium sulfate. The raw juice is then cooked in an autoclave to create fermentable sugars.

- Efficiency: This method takes only 4 to 8 hours to extract sugars.

- Drawbacks: While efficient, this method uses chemicals and lacks roasting, which sacrifices the rich, smoky flavors traditional mezcal enthusiasts love.

Autoclave Method

Think of the autoclave as a giant pressure cooker. It’s slower than the diffuser method but still significantly faster than traditional techniques.

- Process: Pressurized steam cooks the agave, breaking fructans into fermentable sugars. The resulting juice is fermented using natural or selected yeast strains.

- Time: Typically takes about 10 hours.

- Usage: Commonly used in tequila production and for large-scale mezcal production.

- Flavor Impact: While effective, this method produces a cleaner flavor profile, lacking the depth and smokiness found in more traditional methods.

Choosing the Right Cooking Method

The choice of cooking method depends on the producer’s goals and resources.

- Small Batch Mezcal Producers: Often opt for traditional methods to highlight unique regional flavors and maintain artisanal authenticity.

- Large-Scale Mezcal Producers: May use modern techniques to streamline production and meet higher demand.

Cooking agave is the heart of mezcal production, where science meets tradition. Whether using ancient subterranean ovens or modern autoclaves, the process transforms raw agave into the complex spirit we love. Understanding the nuances of each method not only deepens our appreciation for the mezcal but also highlights the dedication of the mezcaleros who craft it.

By preserving traditional practices while embracing sustainable innovation, the mezcal industry continues to honor its roots while adapting to a global audience. The next time you savor a glass of mezcal, remember the incredible journey that began with cooking the humble agave.

Sustainability in Cooking Agave

With the increasing popularity of mezcal, sustainability has become a critical concern. Producers are exploring ways to balance traditional practices with environmental responsibility, such as:

- Efficient Use of Resources: Optimizing wood usage in conventional ovens.

- Preservation of Traditional Techniques: Emphasizing ancestral agave harvesting and cooking methods helps maintain the cultural and artisanal heritage of mezcal production.

- Denomination of Origin: Cooking methods must adhere to the guidelines set by the Denomination of Origin for mezcal, ensuring authenticity and quality

- Alternative Fuels: Exploring renewable energy sources for autoclaves.

- Reforestation Efforts: Planting agave to offset harvesting.